Home

Contact

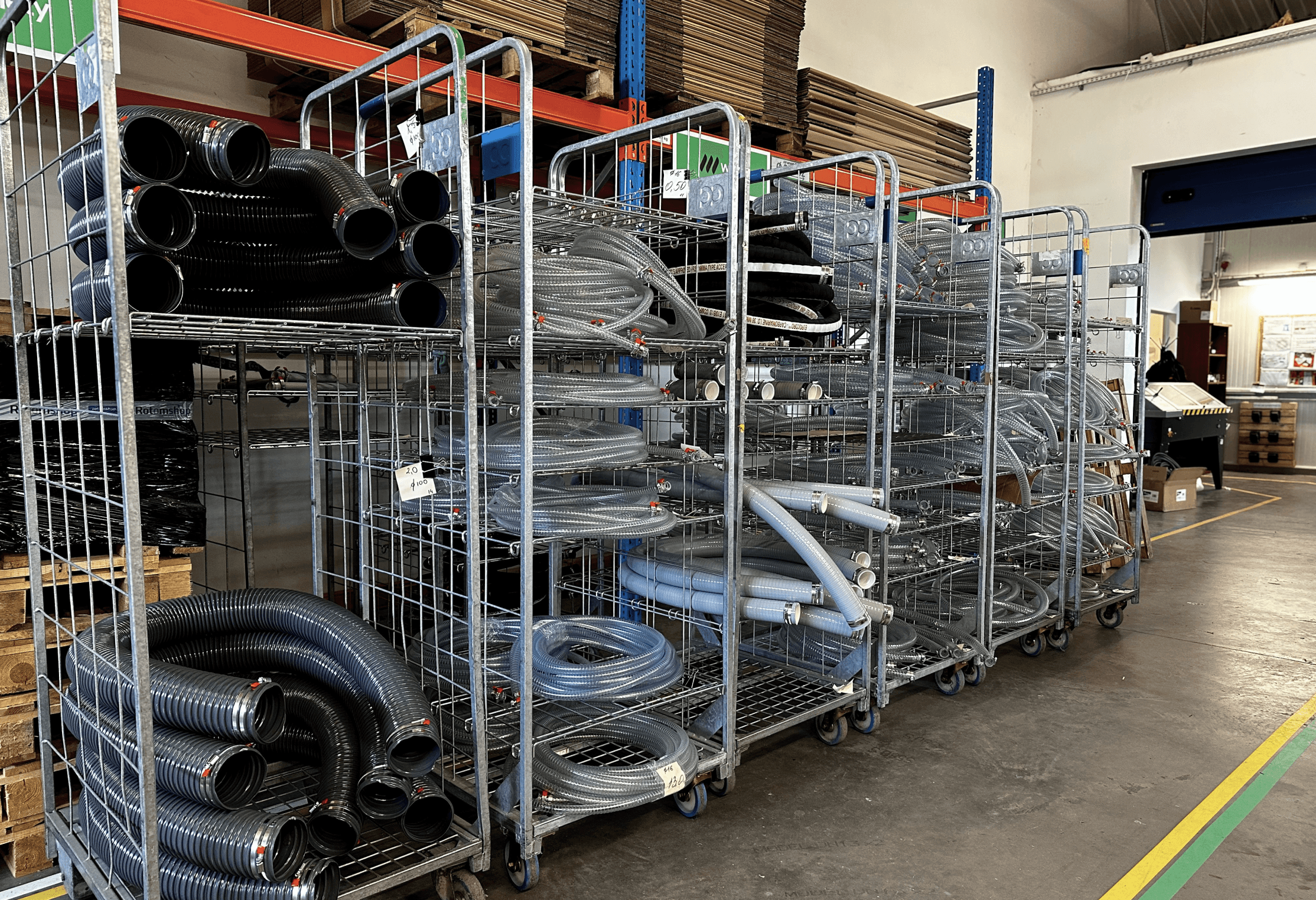

hoses KIT system

All components in one box

1

Eliminate overstock cost

2

Shorten production times

3

No pre-production cost

Just plug it.

Shorten production times

1

All components assembled together

2

Indicated connection points

3

Easy to plug by anybody

Effective purchasing

No unnecessary work & cost

1

Eliminate overstock cost

2

Calculate the EOQ faster

3

Prepare orders faster

We prepare a dedicated version of the configurator tailored to your needs

No pre-production cost

They are equal to cost of goods

1

Labor cost

2

Working station

3

Tools & safety gear

Resume

3 reasons to start the revolution

1

Just plug it.

Shorter production times

Expected over

%

2

Eko configurator

Total overstock elimination

Expected over

%

3

No pre-production

Cut unnecessary production costs

Expected over

%

Statistic boat

Lenght

29.92 ft

Cabins/people

2/10

Fuel tank

309 l

Water tank

50 l

Engines

2x250 HP

Max speed

45 knots

Components included

Fuel hoses

35.27 ft

Water hoses

48.82 ft

Sanitary hoses

21.65 ft

Vent hoses

23.29 ft

Clamps + plugs

176 pcs

Price of the kit

184.32 €

129.03 ft of hoses

88 clamps + 88 safety plugs

272 pre-production operations done

+ ready for quick instalation by anybody

All our customers have to face

Similar challenges

We have thoroughly analyzed your industry to create a product that is a gamechanger for your company

1

Few models of boats

2

Hundreds of options

3

Every boat is different

4

Short production series

5

Often changing hose lenghts

Data speaks for itself

Statistic order

Coils

Hose sections

x

800

Number of coils

54

x

Total length required

1 800 mt

1 378 mt

Total weight of coils

963 kg

702 kg

Number of operations

17 078

0

Total hose cost

5.975 € (coils)

4.716 € (cm)

+ Cost of operations

17 078

0

Statistical workforce problems:

Number of educated employees

40%

Time needed for job preperation

3 months

Time they are leaving company

15 months

Communication in local language

80%

/002

Statistic pre-production.

Watch a short video

for more details.

Statistical pre-production

Coils

Hose coils to unwrap

54

0

Lenght measurement

800

0

Cutting operations

800

0

Hose spiral cutting

700

0

Spiral trimming

1 400

0

Fitting taking

627

0

Fitting inserting

627

0

Clamp taking

3 200

0

Clamp inserting

3 200

0

Clamp screwing

3 200

0

Plug inserting

3 200

0

Total operations

17 078

0

Typical doubts of potential customers

Our current smart OEM kits customers also had many doubts before buying.

Below we list all the concerns we've encountered during our initial visits.

How can smart kits be more profitable than hoses in coils?

Buying hoses in coils always generates too much inventory and uses unnecessary capital.

This pushes the company to cover large pre-production costs: labor, tools, work station.

The cost of workers to manually cut the hoses costs as much as the cost of hoses.

We can cut the hoses ourselves, why we should need your kits?

All our customers cut their hoses themselves before switching to smart OEM kits.

Calculate the cost of a man-hour and see how many hoses the employee can cut in that time. Cutting hoses is a very simple operation, the problem is that it takes a lot of time and costs a lot.

We do not have mass production, are the kits good for smaller shipyards?

None of our clients, even the largest ones, have mass production. Each of them places orders

for many types and versions of boats in single quantities. Short-series production is our specialization and we have an organized production process for it.

We have large variety of options to go with such kit solution!

Each of our clients has a large number of options, even if have only a few models in the offer.

For a boat manufacturer offering 10 models, the average number of options is 150. Our typical shipping time for options is 7 days from the date of order.

We often change boat design, it is not the solution for us!

Statistically, our customers change their boat design once every two months. The discrepancy

with the length applies to new designs, we can send a free kit to make corrections. This way we effectively eliminate the problem of correct lengths.

We have to big stock to convert coils to kits now!

All our customers had their own stock before they decided to purchase smart OEM kits.

We can collect and use the customer's current goods first. Delivering kits made of our components is the next step.

We don’t have time for measuring hose lenghts on current models!

We almost always see a difference between the length of the hoses in the documentation

vs reality. Our clients almost always have neither the time nor resources to perform measurements. That's why we always send our team to do this work at our expense.

/004

Typical doubts.

Watch a short video for more details.

No risky implementation process

You don't take any risk until you find out that it's a good solution for you. We always apply this rule when the client is not ready

to make a decision.

1

We provide hose samples and certificates for the marine market, first

We have over 25 years of experience in the maritime market. Each hose is used by leading European boat manufacturers. Each of the offered hoses has appropriate certificates.

2

We take responsibility for measuring the correct lengths of hoses

We can send our own team to take length measurements.

We assume the responsibility and costs of measurement operations.

Any mistakes will never be at your expense.

3

We make the first kit for each boat free of charge

There are discrepancies in the length of the hoses when assembling

the first boat of a new design. We will prepare a free set according

to the dimensions given in the project to make adjustments in reality. Only after making corrections, our production documentation is created.

4

We will be present when the first kits are installed.

When installing a free kit, we do more than just detect possible irregularities. We check whether the hose markings are clear to all employees and whether they speed up their work? If any doubts arise, we redesign the marking systems to make them more understandable.

5

We will secure a stock for you so that deliveries are on time.

All our suppliers are involved in the smart OEM kits project.

They secure product availability, for example through consignment warehouses.We provide customers with an e-solution so that they can control the security of goods for their needs.

6

We will use up your hoses first, then ours.

Switching to smart OEM kits has no additional costs for our customers. Every customer who decided on smart OEM kits had their own supplies. We use them first so that customers can release their funds.

After sales

service design

Warehouse

Purchasing

Accounting

Producton

Quality controll

1

Packing list on the pallet for faster checking

2

Extra black foil on the top against rain

3

Transparent foil instead of black for faster box identification

4

Packing pallets by sets (green/red)

Separate packing for different facilities

5

Less hoses out of the box

6

Cross taping the box

7

Bundling by ties not by foil

Ready to join the revolution?

Contact us

SPECFLEX SP. Z O.O.

Aleja 1000-lecia P.P. 8,

15-111 Białystok

Tel: +48 577 800 260

e-mail: biuro@specflex.pl

Terms and conditions

Privacy policy